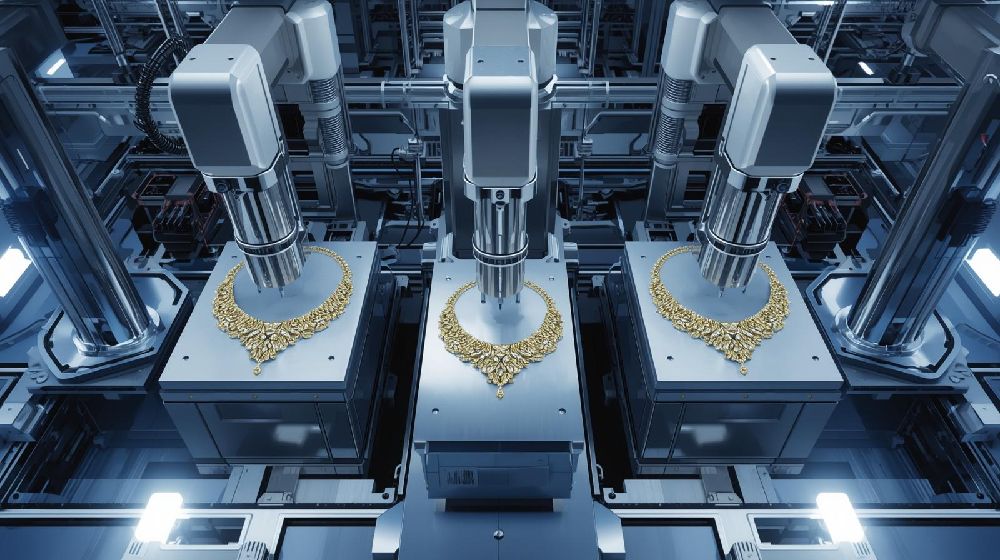

The gold jewelry industry has traditionally been associated with skilled artisans, intricate craftsmanship, and time-intensive production processes. While artistry remains at the heart of jewelry making, modern manufacturing methods are transforming how gold jewelry is produced. One of the most influential approaches driving this transformation is lean manufacturing.

Originally developed in the automotive industry, lean manufacturing focuses on reducing waste, improving efficiency, and maximizing value. Today, this approach is reshaping gold jewelry production—making it faster, more precise, cost-effective, and sustainable without compromising quality.