In today’s competitive jewelry industry, precision is no longer optional—it is essential. As designs become more intricate and material costs rise, modern jewelry factories are rapidly adopting zero-error production lines. These systems aim to minimize defects, reduce material waste, and ensure consistent quality from design to final polish. The shift marks a significant evolution in how jewelry is manufactured and valued.

What Zero-Error Production Really Means

Zero-error production does not imply perfection by chance; it is the result of controlled processes, data-driven decisions, and advanced technology. Every stage—from digital design and casting to finishing and quality checks—is optimized to prevent mistakes rather than correct them later.

This proactive approach transforms quality control from an inspection phase into an integrated manufacturing philosophy.

The Role of Digital Design and Simulation

Modern production lines begin with digital modeling and simulation. CAD software allows manufacturers to test proportions, tolerances, and structural integrity before any material is used. Potential weaknesses are identified early, eliminating costly redesigns and reducing gold or silver loss.

By resolving errors at the design stage, factories significantly improve production efficiency.

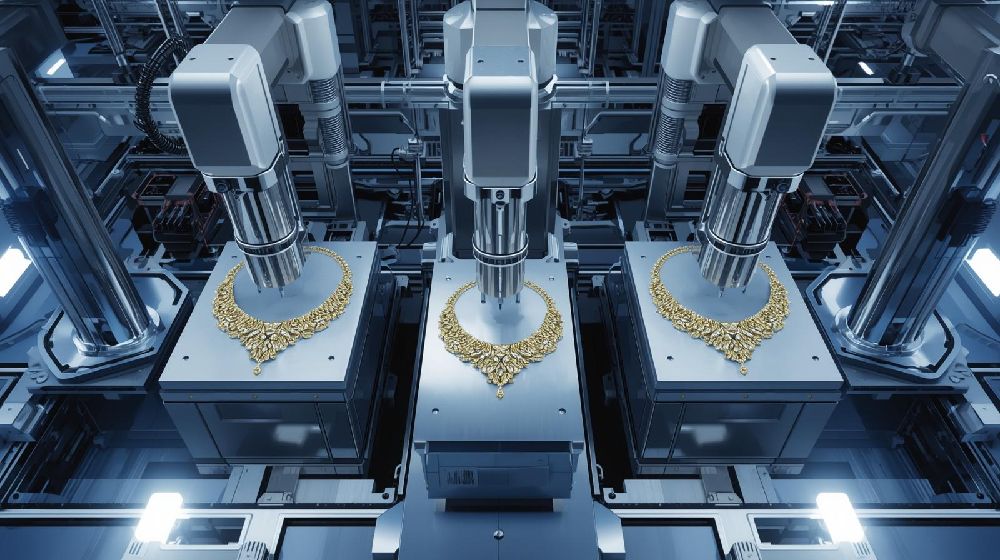

Precision Machinery and Automation

High-precision CNC machines, laser welding systems, and automated polishing units play a central role in zero-error environments. These machines operate with micron-level accuracy, ensuring consistency across large production volumes. Automation reduces dependency on manual corrections, which are often the source of variability.

Consistency is critical when producing jewelry at scale without compromising craftsmanship.

Real-Time Monitoring and Data Integration

Advanced factories now rely on real-time data tracking throughout the production line. Sensors and software systems monitor temperature, weight, alignment, and finishing quality at each stage. Any deviation from set standards triggers immediate adjustments, preventing defective pieces from moving forward.

This continuous feedback loop strengthens process reliability and output quality.

Reducing Material Waste and Cost

Precious metals demand responsible usage. Zero-error production significantly reduces scrap and rework, ensuring optimal material utilization. Accurate casting, controlled alloy composition, and precision finishing all contribute to lower wastage and higher yield per batch.

Responsible production benefits both the manufacturer and the environment.

Enhancing Worker Skill and Focus

Rather than replacing craftsmanship, zero-error systems enhance it. Skilled artisans focus on fine detailing and finishing while machines handle repetitive, precision-based tasks. This balance improves productivity and allows human expertise to shine where it matters most.

Technology becomes a partner to craftsmanship, not a replacement.

Meeting Global Quality and Compliance Standards

Zero-error production lines help factories meet strict international quality and export standards. Consistency, traceability, and documented processes increase buyer confidence and strengthen brand credibility in global markets.

For jewelry brands, this reliability translates into trust and long-term partnerships.

The Future of Jewelry Manufacturing

As consumer expectations rise and sustainability becomes a priority, zero-error production will continue to shape the future of jewelry manufacturing. Factories that invest in precision, data, and process control are better equipped to deliver superior products with minimal waste.

In modern jewelry factories, quality is no longer inspected at the end—it is engineered at every step.